Please note that this blog is archived and outdated. For the most current information click here!

WorkingMouse & MEC Mining Shine at Unearthed Hackathon

A hackathon is a weekend where programmers, domain experts, designers and problem owners collaborate to create a prototype and pitch an idea. This isn't a tech revolution, however it's really great experience. Over the past weekend, WorkingMouse and MEC Mining teamed up and rocked the Unearthed Hackathon. The event was held at River City Labs in Fortitude Valley, Brisbane.

The problems for the hackathon were posted by Newcrest and BHP Coal. The two Newcrest problems were rock fragmentation of block caves and predictive maintenance on cyclone pumps. The two BHP problems were the recognition of geophysical logs and the supply chain custody of samples.

Over the weekend, our team - fondly named WorkingMine - ended up working on the supply chain custody of samples' problem. The problem was that samples were being lost or moving slowly through the custody chain. On the surface one might assume that the problem has been solved by Australia Post and other courier services, but the unique problem in mining is that the samples go off due to oxidisation which can be accelerated by temperature and more fragmentation. This makes it important to not only to be able to locate the sample, but to be able to monitor it and allow the labs to upload results to minimise human error and administration overhead.

The plan was to geolocate each sample and then report this and other metrics. For our team's live demo we built a GPS-enabled electronics device to send locations to a developer API. (A classic example of the possibilities emerging with the Internet of Things revolution). We had the location displayed in real-time on a map by mimicking a truck driving down the East Coast of Queensland. The audience then got to watch the pins appear on the map as the truck moved. We geofenced a facility and as the truck entered this, a push notification was sent to a mobile that was placed on the judge's desk, alerting them of the samples location. They could then click on the pin to find out more information about the sample.

This was a very cool demo and I may be a little biased, but our demo was possibly the most advanced of the evening. So how did we achieve so much in a short amount of time? The answer is our low-code platform for rapid application development. In the rest of this post we are going to dive deep into the weekend. Not to spoil some of the fun, but within half an hour of starting on Saturday morning we already had over 90,000 lines of code completed! This is all thanks to efficient use of APIs and, of course, our Innovation Platform.

Friday Night - Day 1

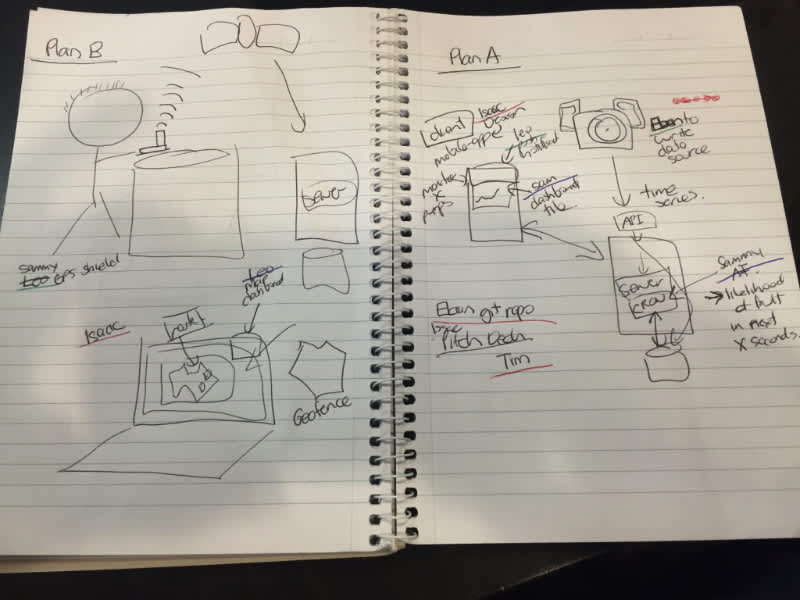

Friday night was all planning (and a couple of beers). We had the opportunity to talk with the problem owners and mentors about the problems in depth. Two problems stood out for us. Plan A was - predictive maintenance on cyclone pumps from Newcrest - and Plan B was - supply chain custody of samples from BHP Coal. Here is a photo of our conceptual maps.

We realised very quickly that Plan A hinged on the data set and how well we could predict the pump failures. So, after understanding the data set and using some machine learning algorithms - specifically we used a random forest regression as it seemed a good fit - we could only predict within a 15 day range and the problem owner wanted a larger range. Given the time restraints of the weekend, we pivoted and changed to Plan B, the supply chain custody of samples.

.png)